Guardrail w beam

1. Preparation: Determine the installation location, quantity and size of the guardrail, etc., and purchase the required guardrail materials and accessories. At the same time, check whether the installation site needs to apply for relevant approval procedures.

2. Cleaning work: Clean up lawns, shrubs and other debris on the installation site to ensure that the installation site is smooth and clean.

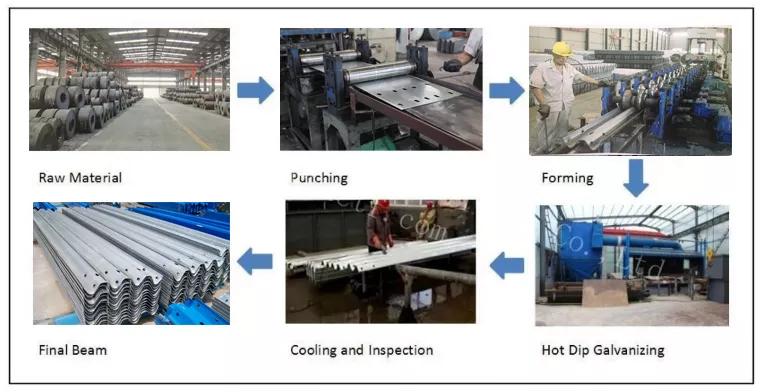

Production flow chart of Guardrail beam

Product parameter of Guardrail beam

Normal Sizes | Length(mm):2000/2320/3200/3810/4000/4320 W:306/310/312/380 Height(mm):80/82/83/85 Thickness(mm) :2.5/2.75/3.0/4.0 Available in different sizes. |

Materail | S235JR,S355JR |

Profile | W beam , Thrie beam |

Surfacce treatment | Hot dipped galvanized or plastic sprayed coating |

Applicabele Standards | JT/T2811995(Corrugated Sheet Steel Beams For Expressway Guardrail - China), AASHTO M180(Corrugated Sheet Steel Beams For Highway Guardrail - USA), RAL RG620 (German) or any other International Standards |

Base Steel | Grade S235JR ( according to DIN EN 10025 and Gr. Daccording to ASTM A283M) or S355JR (ASTM A529M 1994) |

Zinc layer thickness | 550g/m2 (40µ) or 1100 g/m2 (80µ) or 1200 g/m2 (85µ) or as per your request |

Guardrail installation details usually include the following steps:

1. Preparation: Determine the installation location, quantity and size of the guardrail, etc., and purchase the required guardrail materials and accessories. At the same time, check whether the installation site needs to apply for relevant approval procedures.

2. Cleaning work: Clean up lawns, shrubs and other debris on the installation site to ensure that the installation site is smooth and clean.

3. Marking and measurement: According to the required guardrail size, mark the position and length of the guardrail on the installation ground, and use measuring tools to ensure accuracy.

4. Install the pillar: according to the line, dig holes with appropriate depth on the installation ground, and then insert the guardrail pillar into the hole. Use a level to ensure the pillar is vertical and cement or concrete to secure the pillar.

5. Connect the guardrail plate: Install the guardrail plate between the pillars according to the required guardrail length. Use a matching connector to connect the guardrail plate to the pillar to ensure firmness.

6. Install ends and doors: Install guardrail ends and doors if needed. The use of specialized end and door fittings ensures the integrity and convenience of the guardrail.

7. Adjustment and trimming: After installation, check the horizontality and verticality of the guardrail and make necessary adjustments. For guardrail panels that require custom dimensions, trimming may be required during installation.

8. Inspection and testing: After completing the installation, conduct a comprehensive inspection of the guardrail to check whether the welding points, connectors and positions are firm and reliable. Test the door on and off to ensure smooth opening and closing.

The above is the general installation details of the guardrail, the specific operation may vary depending on the actual situation. Before installation, it is recommended to refer to the installation manual of the guardrail or consult a professional installer to ensure correct installation and use.

Packed guardrail beam ready to ship