Highway guard

During the normal operation of the highway, the guardrail beam can be easily inserted into the pre-set plug hole at the opening by using the plug column to play the role of isolation and protection. At the same time, it echoes the guardrail belt on the outside of the highway, which is neat, uniform and beautiful. When the vehicle collides with it, because the corrugated steel guardrail has good crashworthiness and energy absorption, it is not easy to be crashed, but also plays a good role in protecting the vehicle and the driver and passenger.

The galvanizing process of guardrail usually includes the following steps:

1. Surface treatment: First of all, the guardrail needs to be treated on the surface, such as removing oil, rust, dirt and so on. This can be achieved through chemical cleaning, sandblasting, rust remover and other methods to ensure the adhesion and uniformity of the coating.

2. Pickling: The guardrail is immersed in an acid bath, and after a period of pickling treatment, to remove deeper oxides and impurities, while providing a clean surface for subsequent galvanizing.

3. Pretreatment: Dip the guardrail into the pretreatment device for surface activation treatment. This can be done by soaking in an activator or using electrolytic activation methods to improve the bonding ability of the galvanized layer to the substrate.

Specification of Guardrail Beam

Normal Sizes | Length(mm):2000/2320/3200/3810/4000/4320 W:306/310/312/380 Height(mm):80/82/83/85 Thickness(mm) :2.5/2.75/3.0/4.0 Available in different sizes. |

Materail | S235JR,S345JR |

Profile | W beam , Thrie beam |

Surfacce treatment | Hot dipped galvanized or plastic sprayed coating |

Applicabele Standards | JT/T2811995(Corrugated Sheet Steel Beams For Expressway Guardrail - China), AASHTO M180(Corrugated Sheet Steel Beams For Highway Guardrail - USA), RAL RG620 (German) or any other International Standards |

Base Steel | Grade S235JR ( according to DIN EN 10025 and Gr. Daccording to ASTM A283M) or S355JR (ASTM A529M 1994) |

Zinc layer thickness | 550g/m2 (40µ) or 1100 g/m2 (80µ) or 1200 g/m2 (85µ) or as per your request |

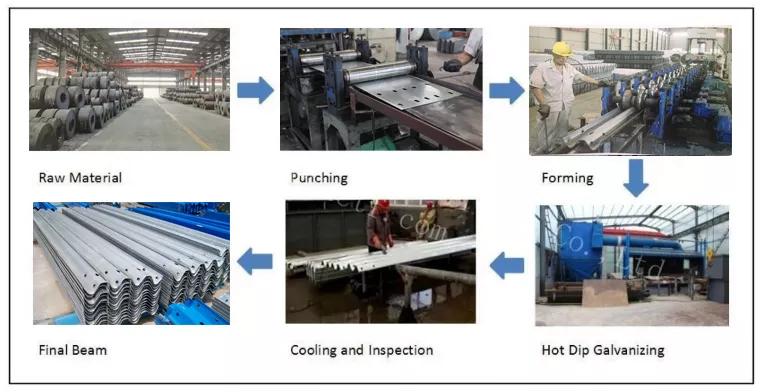

Production Flow Chart of Guardrail Beam

4. Hot dip galvanizing: Dip the pre-treated guardrail into the galvanizing tank, and the zinc liquid in the tank will be heated to the melting point. The guardrail is soaked in zinc liquid for a period of time, and after the zinc liquid reacts with the substrate, a layer of zinc-iron alloy coating will be formed on the surface of the guardrail to protect the guardrail from corrosion.

5. Post-treatment: After the completion of galvanized, the guardrail needs to be post-treated, such as cooling, cleaning, coating anti-corrosion coating, etc. This helps to further improve the corrosion resistance and appearance quality of the guardrail.

Please note that the specific guardrail galvanizing process may vary by manufacturer and specific requirements. When performing the galvanizing process, ensure that the relevant standards and operating techniques are followed to obtain a high quality guardrail galvanizing layer.

Installation Rendering of Guardrail Beam

Cold galvanized: the metal surface of the high-speed guardrail is cleaned and pickled first, and then a layer of zinc alloy coating is established on the surface of the high-speed guardrail by spraying, brushing and other methods. This method is simple to operate, does not require a high temperature environment, and is environmentally friendly. But its coating thickness is thin, durability is not as good as hot dip galvanizing.

Packaging and Delivering of Guardrail Beam