Guardrail barrier

FORST guardrail beam hot-dip galvanizing is a commonly used anti-corrosion process,

1. Preparatory work: Clean and surface-treat the guardrail to remove oil, rust and other impurities on the surface to ensure the adhesion of the coating.

2. Pickling: immerse the guardrail in an acidic solution such as hydrochloric acid or sulfuric acid for pickling. Pickling can remove oxides and rust on the surface and improve the adhesion of the coating.

3. Pretreatment: The pickled guardrail is subjected to wet coating pretreatment. Phosphating, pickling and phosphating are usually used to form a layer of pre-coating to enhance coating adhesion and anti-corrosion performance.

4. Hot-dip galvanizing: immerse the pretreated guardrail in molten zinc solution for hot-dip galvanizing. Hot-dip galvanizing is to firmly combine the zinc coating with the substrate to form a uniform zinc layer to provide good corrosion resistance.

5. Finishing: Finish the guardrail after hot-dip galvanizing, remove excess zinc liquid and clean impurities, so as to ensure the surface finish and appearance quality.

FORST guardrail beam hot-dip galvanizing is a commonly used anti-corrosion process,

1. Preparatory work: Clean and surface-treat the guardrail to remove oil, rust and other impurities on the surface to ensure the adhesion of the coating.

2. Pickling: immerse the guardrail in an acidic solution such as hydrochloric acid or sulfuric acid for pickling. Pickling can remove oxides and rust on the surface and improve the adhesion of the coating.

3. Pretreatment: The pickled guardrail is subjected to wet coating pretreatment. Phosphating, pickling and phosphating are usually used to form a layer of pre-coating to enhance coating adhesion and anti-corrosion performance.

4. Hot-dip galvanizing: immerse the pretreated guardrail in molten zinc solution for hot-dip galvanizing. Hot-dip galvanizing is to firmly combine the zinc coating with the substrate to form a uniform zinc layer to provide good corrosion resistance.

5. Finishing: Finish the guardrail after hot-dip galvanizing, remove excess zinc liquid and clean impurities, so as to ensure the surface finish and appearance quality.

Specification of Guardrail Beam

Normal Sizes | Length(mm):2000/2320/3200/3810/4000/4320 Height(mm):80/82/83/85 Thickness(mm) :2.5/2.75/3.0/4.0 Available in different sizes. |

Materail | S235JR,S355JR |

Profile | W beam , Thrie beam |

Surfacce treatment | Hot dipped galvanized or plastic sprayed coating |

Applicabele Standards | JT/T2811995(Corrugated Sheet Steel Beams For Expressway Guardrail - China), AASHTO M180(Corrugated Sheet Steel Beams For Highway Guardrail - USA), RAL RG620 (German) or any other International Standards |

Base Steel | Grade S235JR ( according to DIN EN 10025 and Gr. Daccording to ASTM A283M) or S355JR (ASTM A529M 1994) |

Zinc layer thickness | 550g/m2 (40µ) or 1100 g/m2 (80µ) or 1200 g/m2 (85µ) or as per your request |

Features | Great corrosion resistant, high intensity, long and durable, with good impact resistance, low cost, long life, higher security,environmental protection, etc. |

Relevant Parts | Required for Guardrails Post, Spacer (C, U and Sigma types etc) and Fasteners, Bolts&Nuts,Terminal,Reflectors |

MOQ | 100pcs |

Price Terms | FOB,CFR,CIF |

Payment Terms | T/T,L/C at sight |

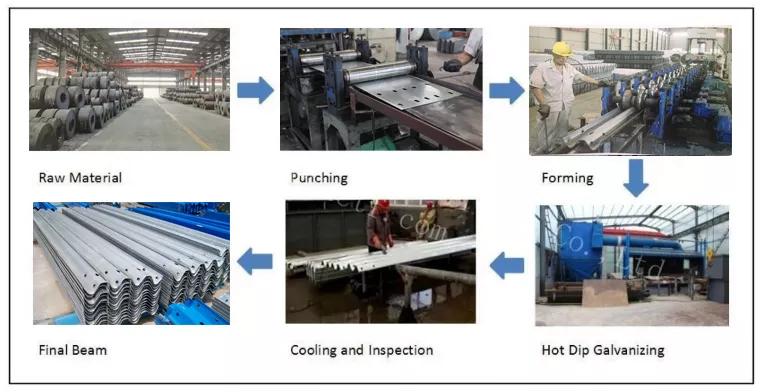

Production Flow Chart of Guardrail Beam

Production workshop of Guardrail Beam

Installation Rendering of Guardrail Beam

Packaging and Delivering of Guardrail Beam